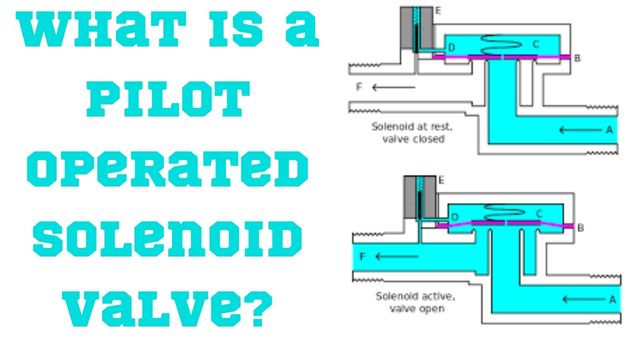

What is a Pilot Operated Solenoid Valve?

Pilot Operated Solenoid Valve- The pilot solenoid valves are using differential pressure to open and close. The pilot proportional solenoid valve control circuit is pressure sensitive and these valves are going to open and close by the pressure change. The pilot-operated solenoid valves are going to use less electrical power for working. The other thing is that you can set a precise range of the pressure and temperature to operate the pilot solenoid valves.

The pilot solenoid flow control valve work at a faster pace and allows a better pace of the liquid flowing through it. You can use the pilot-operated valves to control the flow of a large medium, and these valves are more economical as compared to the directly operated solenoid flow control valves.

In this article, we are discussing what are the pilot-operated solenoid flow valves and their advantages:

Advantages of the Pilot solenoid valves:

There are certain advantages of pilot-operated valves:

To Control the Flow of Large Medium:

It is the control of the pilot-operated valves that makes them the number one choice to manage the flow of liquid in the large piping system. The pilot solenoid valves are excellent for controlling the flow of large mediums and quantities. The proportional solenoid valve control circuit is a pressure and temperature detector, when a certain range is crossed, the solenoid pilot airflow control valve is going to open or close.

This is the main reason these valves are excellent at controlling the flow of liquid in huge quantities. The pilot-operated valves reduce the workload of controlling the liquid flow, as these valves are going to control the liquid flow automatically.

Economical Pressure Valves:

The pilot-operated proportional solenoid valve control circuit is cost-saving, as it is going to use the pressure and temperature for switching on/off. It is the pressure differential for their functionality, this reduces the overall cost of using the pilot-operated solenoid valves.

It is the economical operation of the pilot-operated valves, which makes them the best choice to use in the huge piping network. These valves assist us to control the flow of the liquid as after a certain limit, the valves are going to open and close automatically.

The Less Electrical Power:

There is less voltage required to operate the pilot-operated proportional solenoid valve control circuit as compared to the direct-operating valves. The direct operating valves are using electrical power each time when switching on/off.

On the other hand, you are going to set the instructions to open and close the pilot-operated valves. The proportional valves’ circuit is more sensitive than that of the power-saving solenoid valves.

- WhatsApp Tips: How to disable message reaction notifications?

- How to Find Lost Phone: Tips and Tricks

- How to change your Google password and other useful tips

Conclusion:

The pilot operates a proportional solenoid valve control circuit that is specially designed to control the flow of liquid automatically. These valves are more economical and efficient as compared to the direct operated valves. You can install pilot-operated valves, where a certain range of pressure and temperature is expected. You can program them to open and close at a particular range of pressure and temperature.

What does “pilot-operated valve” mean?

Pressure relief valves known as pilot-operated valves regulate the inlet and output ports of the main valve. Although they resemble spring-loaded valves, they offer the finest alternative for achieving the highest pressure and capacity. These valves provide exceptional overpressure protection performance.

How do safety valves with a pilot operate?

The process medium that a pilot-operated safety valve operates regulates its operation. This is accomplished by feeding system pressure through the pressure-clicking line to the pilot valve that serves as the main valve’s control component. The main valve is then opened and shut using the area in the dome above the main valve piston.

What is the main benefit of using pilot-operated valves versus manual valves?

The ability to remotely activate huge valves with affordable pilot lines is the main benefit of a pilot-operated valve. The larger valves’ more costly working lines might then be kept short to reduce costs. Longer, less expensive pilot lines can be run without sacrificing circuit performance.